Overview

Even a business with strong potential due to optimal pricing and human resource management can be crippled by poor networking. Mismanaged networks can result in a chaotic, unpredictable business environment which will result in long, costly, and disorganized operations. Network optimization allows effective allocation of inventory, reduced costs and lead times, and a stronger bottom line.

The network optimization research has allowed our company to continue to stay ahead of our competition and excel in customer service.”

-Tim Miller, Vice President – Operations Security Contractor Services, Inc.

Hats off to Texas A&M for taking common industry problems with complex components and developing scientific methodologies that are flexible enough to work for any company.”

-Jimmy Roark, Regional Sales Manager NOV Wilson

Challenges

- Unplanned Organic Growth

- Multiple Facilities through M&A’s

- Long Lead Times

- Excessive Inventory

- Competition Driven

- Ineffective Routing/Scheduling

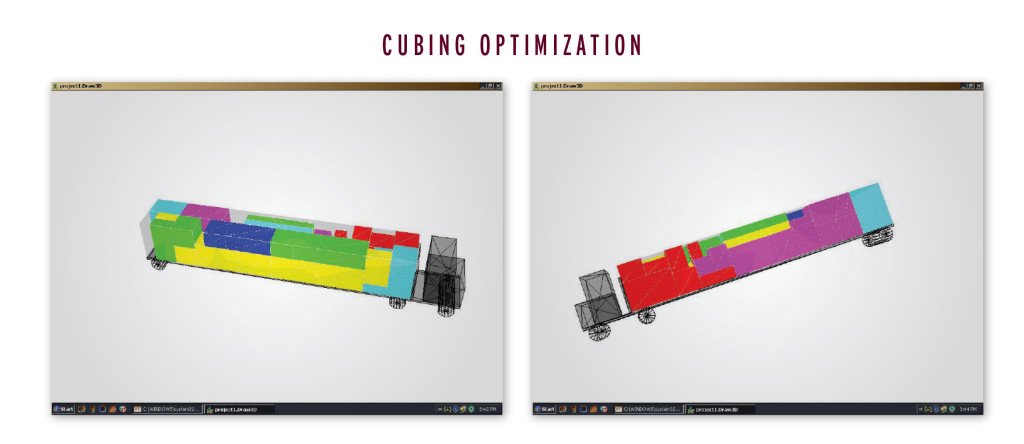

- Poor Truck Capacity Utilization (loading or cubing) Market

- High Cost-to-Serve

Solutions

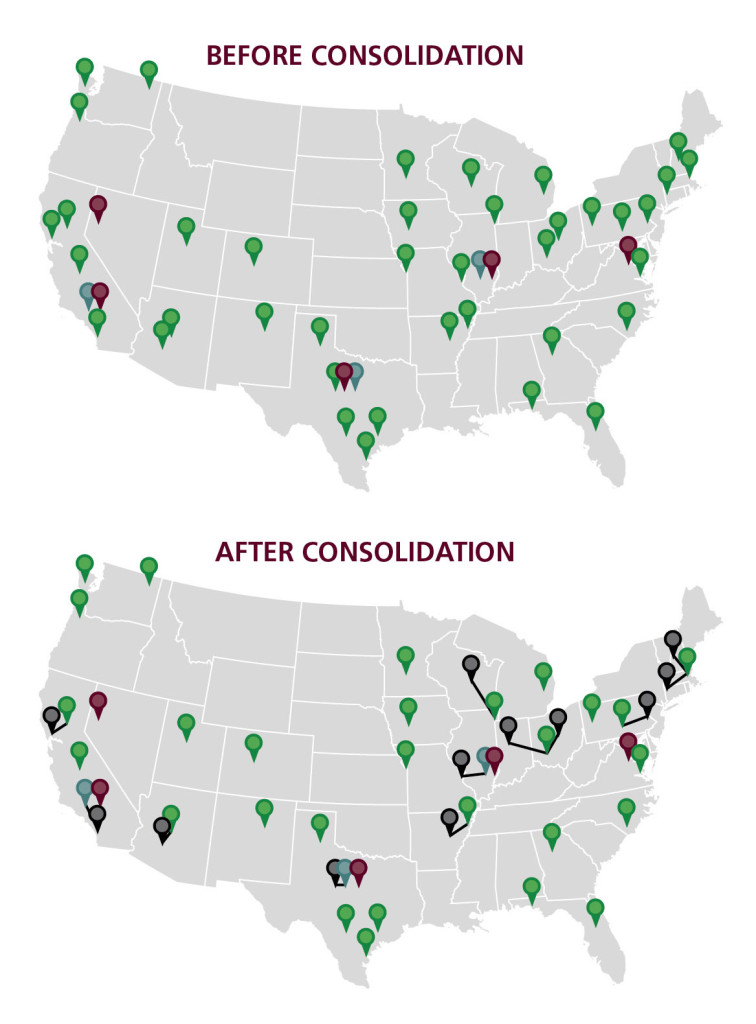

- Facility Network Optimization

- Hub and Spoke Design

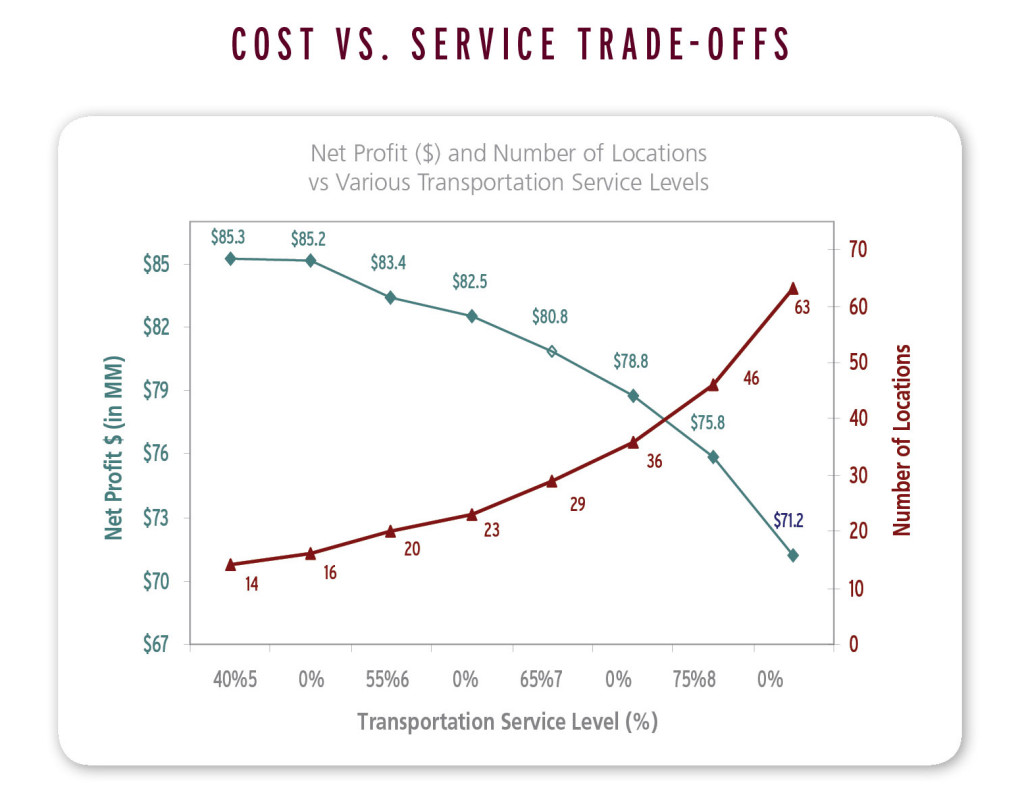

- Service vs. Cost Matrix

Benefits

- Facility Reduction/Expansion, Optimal Network Capacity, and Reduced Operating Expenses

- Optimal Network Configuration

- Aligned Inventory Deployment

- Insight Into Service-cost Trade-offs

- High Profitability

- Reduced Delivery Cost Per Order

- Increased Capacity Utilization